From project to completion, AREMECA takes care of everything !

At the request of a customer, we have developed a test ramp for manifolds.

As a reminder, the manifold is an instrumentation accessory which is used for adjusting and commissioning the measuring device. It is mounted at the interface between the pressure taps and the transmitter. It is used to isolate the transmitter in the event of intervention on the pipeline. It also allows you to re-configure the transmitter zero or to purge the pulse taps (5-way manifold).

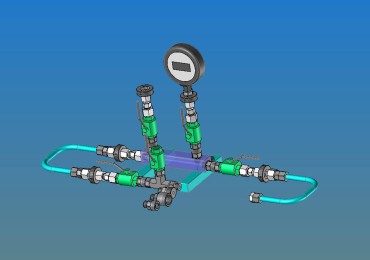

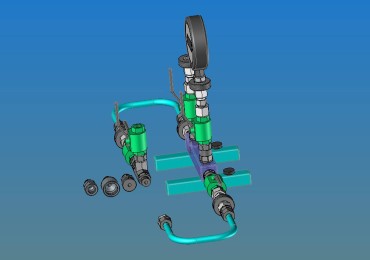

After an initial meeting with the customer to define their needs regarding the functionality of the ramp, we validated the following specifications :

- design a test ramp including a fluid inlet/outlet + 2 outlets to carry out the tests

- introduce stainless steel valves on each outlet - maximum pressure = 200 bar

- provide a 25m flexible hose with an anti-whiplash cable with its set of fittings for connection

- add a 1m flexible hose for purging and/or sampling

Our Design Office therefore worked on this development in order to offer a solution that meets all needs. After the presentation of the project, and a few modifications, the client validated the test ramp.

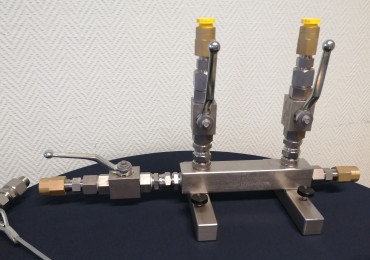

Our machining workshop has launched the manufacture of the various components of the subassembly, based on the detailed plans provided by our Design Office.

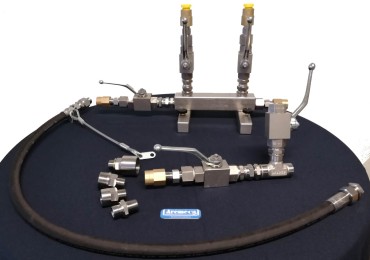

Our technical team then took over to validate the assembly and testing of the test ramp.

Our distributor, the company DIMELCO, which was the commercial relay in this project, came to collect the ramp and all its accessories. During this visit, we supported him on the operation of the test ramp so that he could deliver to his customer in the best conditions.

AREMECA regularly develops products for its customers. Our team is at your service to make possible what others will find impossible.